What are the differences depending on the type of fibers?

Even with the same cotton fiber

There are two types of thread.

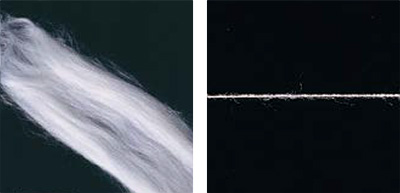

There are two main types of cotton yarn used in T-shirts: carded yarn and combed yarn.

They are graded according to the degree of process that removes impurities and short fibers, which greatly affects quality and price.

Card Yarn

The most basic fiber commonly used, made from cotton that has undergone a carding process (a process that removes about 5% of impurities). You can enjoy the rough taste with a crisp and cool feeling.

Combed Yarn

The fiber is carefully combed to remove about 20% of the defective parts and finished with only high-quality parts. The result is a high-quality product that is shiny, has little fuzz, and is soft to the touch.

How is fiber made?

Ringspun yarn and

What is the difference between open-end yarn?

Cotton fibers, which are the source of cotton thread, are only a few centimeters long and cannot be made into thread as is.

There are various processes to turn cotton into a single thread, and two types of threads (ring spun thread and open-end thread) are produced depending on the spinning method (aligning the direction of the fibers and twisting them while pulling). is completed.

Mixing machine

Wrap

Card Process

Carded Cotton

Comb Combing

Rover

Spinning

Ringspun Yarn

Typical yarn is made using a ring spinning machine and is called “ring spun yarn.” It is spun using the principle of making shimenawa, and the surface of the thread is smooth and strong. Most of our products use this ringspun yarn.

Open End Yarn

It is made using an open-end spinning machine that uses air currents to twist the yarn into yarn. It is characterized by the yarn containing just the right amount of air, giving it a stiff feel.

What is “17s”?

“Count” refers to the thickness of the thread. The higher the number, the thinner and lighter the thread will be.

Also, the “s” (single) after the thread count indicates one thread.

17s = 17th count single yarn

17/2s = 17th count double thread (twisted)

17//2s = 17th 2 lines drawn

*The thickness of polyester thread and nylon thread is expressed in denier (D). The smaller the denier number, the thinner the denier. please note.

About knits and textiles

Knit (knitting)

The material of the T-shirt is knit. When knitting, a surface is formed by creating a loop and then hooking the next loop onto that loop. The texture, breathability, and elasticity change with just one knitting method.

Tenjiku knitting

It is called flat knitting or stockinette knitting. The vertical streaks are visible on the front surface, and the back grain looks a little rough, so you can clearly tell the difference between the front and back grains. This knitted fabric has great elasticity in the horizontal direction and is used for T-shirts, etc.

Waffle knitting (waffle ami)

The official name is thermal, but it is so called because it has a lattice-like uneven pattern on its surface, similar to a waffle. It is a knitted fabric that is highly elastic, highly moisturizing, and does not stick to the skin.

Kanoko knitting

The name comes from the white mottled pattern on the pique’s back. The ridges and openwork are created on the surface to represent the stitch pattern. The area that comes into contact with the skin is small and has excellent breathability.

Reversible mesh

The front side is a normal jersey stitch, and the back side is a modified pique (mesh). It is often used in dry T-shirts as a moisture-absorbing and quick-drying material.

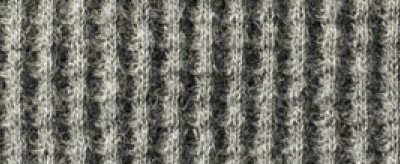

Milling (milling)

Also known as rib knitting or rubber knitting, it has the same stitches on both the front and back stitches, so there is no front or back side of the fabric. It has high elasticity and stretches well in the horizontal direction for an excellent fit.

Smooth knitting

A knitting structure in which two rubber knits are placed back to back and both sides are used as outer material. It has a moderate thickness and excellent elasticity, making it difficult to lose its shape.

Sweatshirt lining pile/fleece (sweet lining pile/urake)

The front side has a jersey stitch, and the back thread is woven into a pile shape to make it float. Sweatshirts are a general term for sports clothing that absorbs sweat, and sweatshirts and parkas are typical items.

Sweatshirt brushed lining (sweet urakimo)

A fabric made by scratching the knitted fabric on the back pile to make it fluffy. It has high heat retention, and the brushed surface gives it a nice finish, making it easier to print.

Textile

The fabrics used for jackets, button-down shirts, trousers, and bags are textiles. Also called fabric, it is basically a fabric made by arranging warp and weft threads in a straight line and crossing them vertically to make a flat surface. The Mihara weave of textiles includes plain weave (taffeta), twill weave (twill), and satin weave (satin).

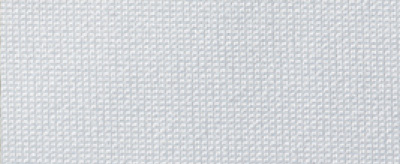

Plain weave (Hiraori)

This is the simplest structure, consisting of one warp thread and one weft thread, and is the most commonly used. It is a durable material that has both sides, and comes in varieties such as taffeta, ponzi, and poplin.

T/C Weather

Called weather cloth, it is a durable, waterproof, high-quality plain fabric that can be used even in bad weather. The tissue density is very high, giving the fabric tension and elasticity.

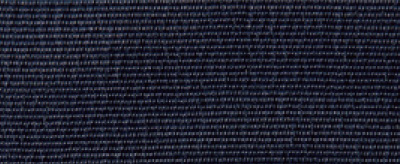

Twill (twill)

It is characterized by the intersecting points of the threads running diagonally, and there are left twill and right twill. The advantage is that it has excellent elasticity and is less prone to wrinkles. Typical examples include serge, gabardine, and denim.

Denim

A thick twill woven fabric woven using colored threads for the warp threads and unbleached threads for the weft threads, with a ratio of 3 warp threads to 1 weft thread. Denim fabric loses color when washed and rubbed repeatedly, and the more you use it, the softer it becomes. Denim fabrics dyed with synthetic indigo are now common.

Canvas

A strong and thick sackcloth also called canvas, originally used as sails for ships. Currently, it is widely used for tote bags and tents.

Oxford

A plain-woven fabric made by aligning two warp threads and two weft threads. It is shiny and has a clear texture. A breathable fabric suitable for summer.

Ripstop

A fabric with a lattice pattern used for parachutes and paragliders. It is a plain weave fabric that is woven with thick threads in a grid pattern, and has a structure that prevents further tearing even if the fabric tears. Rip means to tear, and rip-stop means to stop tearing.

Sheeting

It is thicker than ordinary plain weave or broadcloth. The surface does not reflect light and gives a calm impression. In addition, it is easy to iron, and there are almost no iron wrinkles.

Satin

Satin fabric, also known as satin weave or satin weave, has many warp threads that are exposed, has a beautiful luster, and has a luxurious feel.

Surge

Serge material refers to a fabric that has been added with a clear finish to prevent it from fuzzing. It has a smooth texture and is often used as a material for making uniforms and suits worn by students.

Tasran processed fabric (Tasuranka Kokiji)

Fabric using processed yarn manufactured by pumping air during the spinning stage. The yarn swells by blowing air into it, giving it a natural look similar to natural fibers.

Formaldehyde measures for baby products

Products for babies (products under 90cm)

5001-02 5.6oz High Quality T-shirt (Kids) 90cm

5148-02 5.6oz Baby Romper

5157-02 10.0oz Sweatshirt (pile lining)

5158-02 5.6oz Baby Onesie

*The above product numbers are subject to the following management and measures as baby clothing.

①About the product

Based on the “Act on the Regulation of Household Products Containing Hazardous Substances” stipulated by the government, we conduct formaldehyde tests on the fabrics and accessories used (Ministry of Health and Welfare Ordinance No. 34, Infants and Children A-A0 = 0.05 or less), and test that they are below the standard value. We are getting results.

(Implementing testing agency: Kaken Test Center General Incorporated Foundation)

②About the environment

At United Athle manufacturing plants and domestic distribution warehouses, we conduct formaldehyde environmental measurements and take preventive measures against formalin air contamination.

*Regarding the test results listed in ① on the left, we can disclose them, so if necessary, please contact our sales representative.

Formalin migration during product transfer

We do not manage the transportation or storage of products from our warehouse until they reach the customer.